The Future of AI and Automation in Manufacturing: Transforming Industry Efficiency and Quality

The future of AI and automation in manufacturing is transforming the industry, promising increased efficiency, improved quality control, and groundbreaking innovation. As the AI in manufacturing market grows from $3.2 billion in 2023 to a projected $20.8 billion by 2028, manufacturers are adopting AI technologies to stay competitive and meet global demands.

AI is redefining manufacturing processes worldwide.

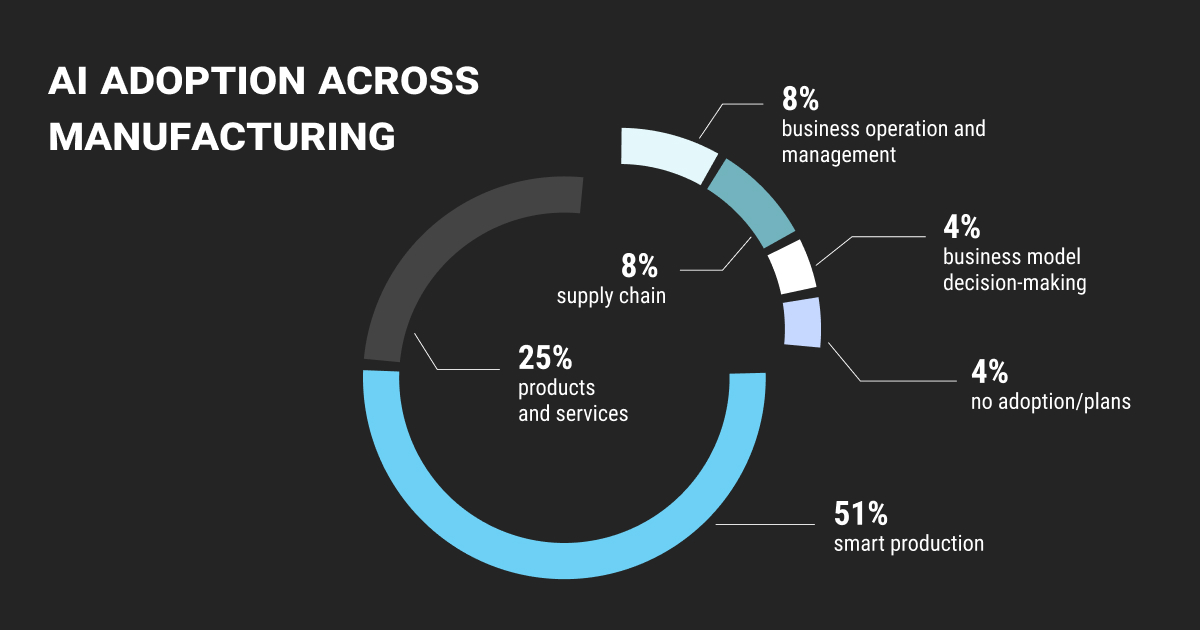

AI Market Growth and Adoption

The rapid adoption of AI in manufacturing highlights its pivotal role in modernizing the industry. By leveraging advanced technologies like machine learning and predictive analytics, manufacturers can streamline operations, reduce costs, and enhance product quality.

Current Market Valuation and Projections

In 2023, the AI manufacturing market was valued at $3.2 billion, but projections estimate exponential growth, reaching $20.8 billion by 2028. This surge is fueled by:

- Increased demand for automation in repetitive tasks.

- The rise of personalized products and mass customization.

- Ongoing investments in industrial AI applications.

According to a report by Markets and Markets, over 70% of manufacturers have already integrated AI into their operations, signaling widespread acceptance and implementation.

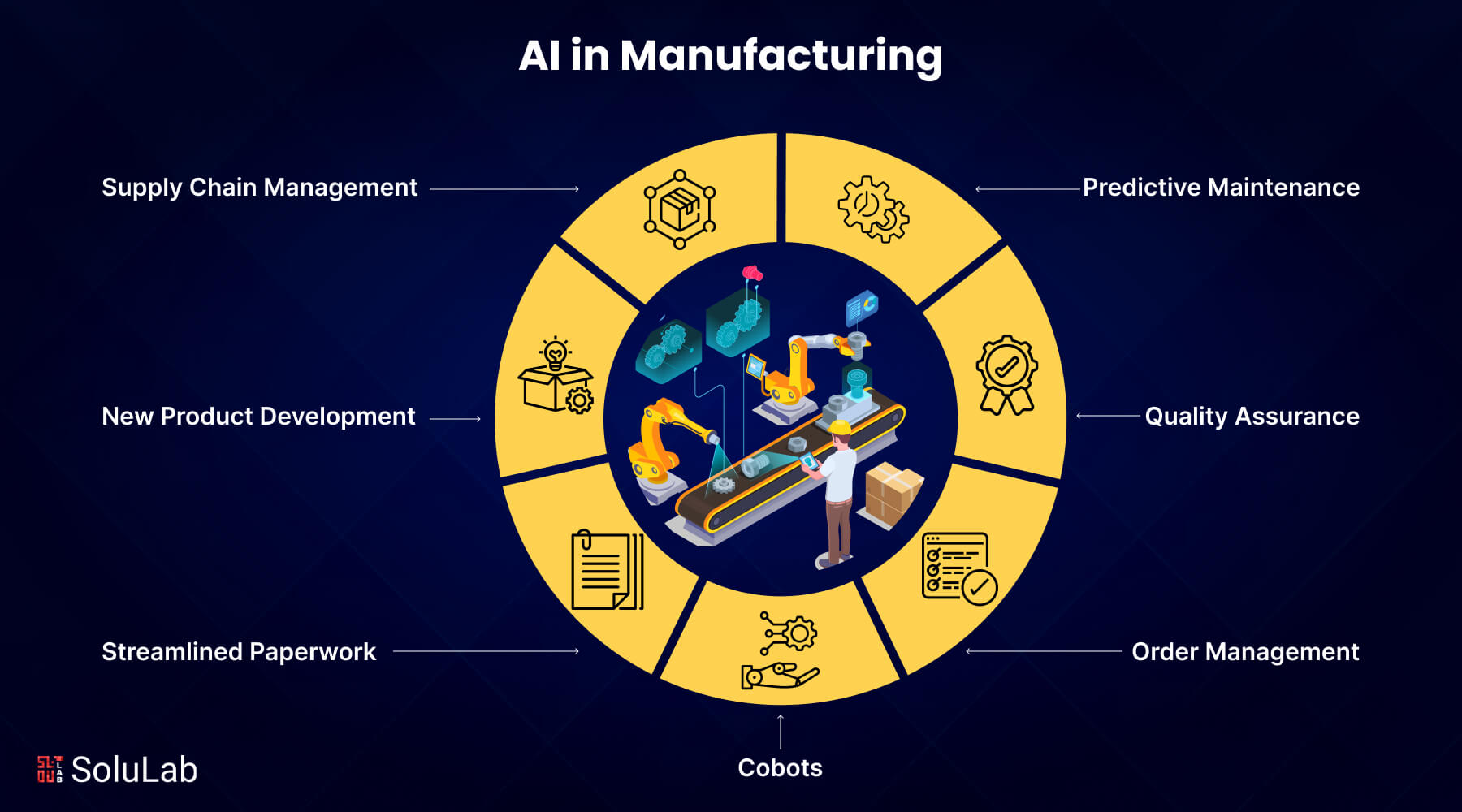

Key AI Technologies and Applications

Several AI technologies are driving the transformation of manufacturing processes, each offering unique benefits to improve efficiency and productivity.

Machine Learning and Deep Learning in Manufacturing

Machine learning algorithms process vast amounts of data, enabling manufacturers to:

- Optimize production schedules.

- Predict and prevent inefficiencies.

- Enhance decision-making with actionable insights.

Meanwhile, deep learning facilitates advanced image recognition, critical for identifying subtle defects during production.

Deep learning applications ensure precision and consistency.

Computer Vision for Real-Time Quality Control

AI-powered computer vision systems are revolutionizing quality control by identifying defects in real-time. Unlike traditional methods, computer vision can:

- Detect imperfections early in the assembly line.

- Minimize waste by reducing defective outputs.

- Improve overall product consistency.

Platforms like DUYTHIN.DIGITAL offer automation tools that integrate seamlessly into manufacturing workflows, enhancing productivity and efficiency. Explore our solutions.

Predictive Analytics for Demand and Maintenance

Predictive analytics has become a cornerstone of modern manufacturing. By analyzing historical and real-time data, AI systems can:

- Forecast market demand, enabling manufacturers to align production with consumer needs.

- Predict equipment failures, reducing downtime and maintenance costs.

For example, manufacturers can use predictive analytics to schedule proactive maintenance, avoiding costly production halts. Learn more about predictive analytics here.

Natural Language Processing in Manufacturing Insights

Natural language processing (NLP) helps manufacturers process unstructured data, such as:

- Maintenance reports.

- Customer feedback.

- Supplier communications.

NLP extracts valuable insights, enabling manufacturers to make data-driven decisions that improve operational performance and customer satisfaction.

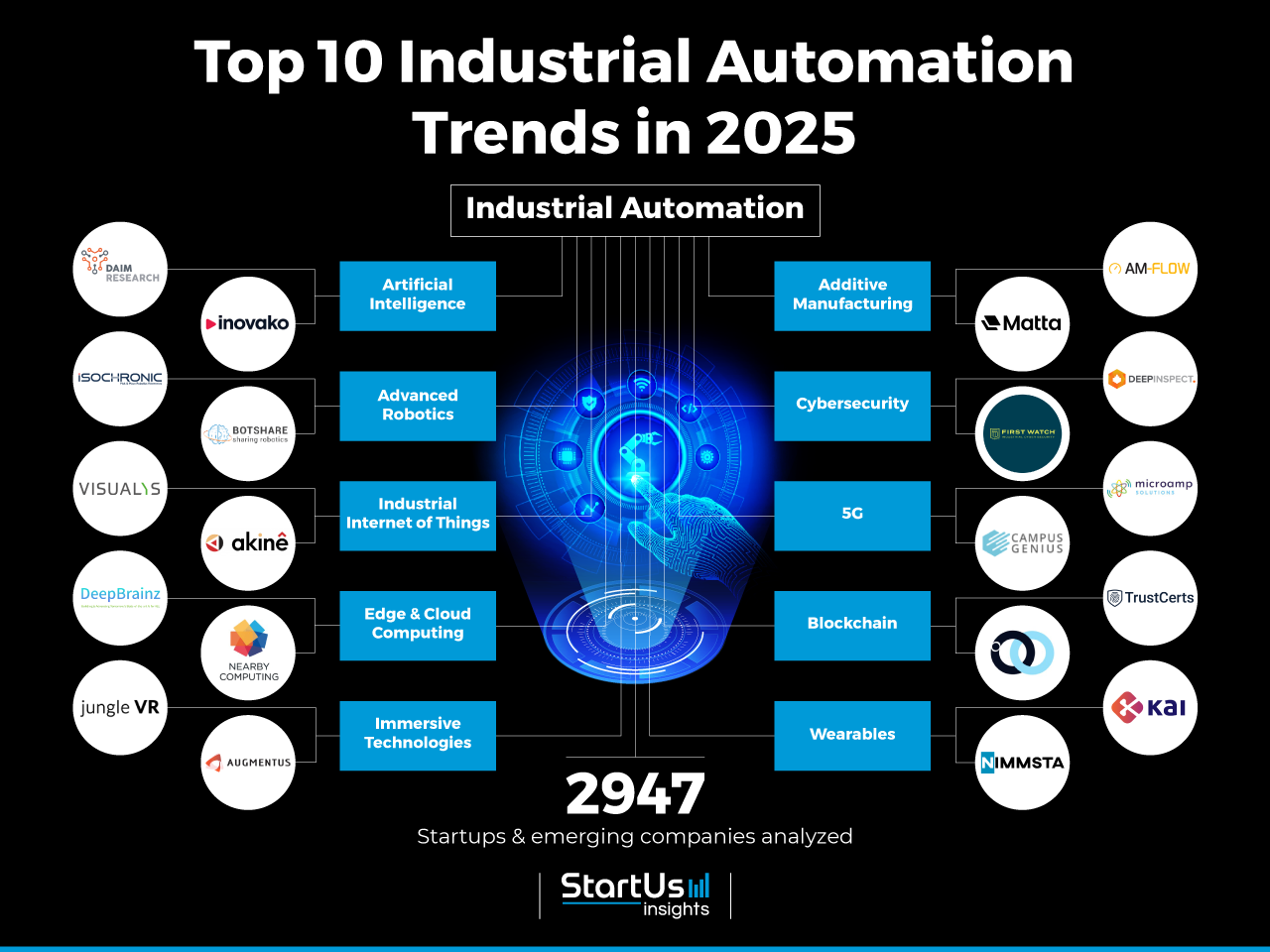

Emerging Trends in AI and Automation

As the industry evolves, several emerging trends are reshaping manufacturing, driven by the integration of AI.

Intelligent Automation: Adaptable Robots

AI-driven robots are becoming increasingly versatile, capable of learning and adapting to their environment. These intelligent systems enable:

- Faster assembly processes.

- Flexible production lines that accommodate varying product designs.

- Enhanced safety for human workers.

Intelligent automation is at the forefront of industry transformation.

Predictive Maintenance for Reduced Downtime

By analyzing sensor data, AI systems can predict equipment failures before they occur. Benefits include:

- Fewer interruptions in production.

- Lower maintenance costs.

- Increased equipment lifespan.

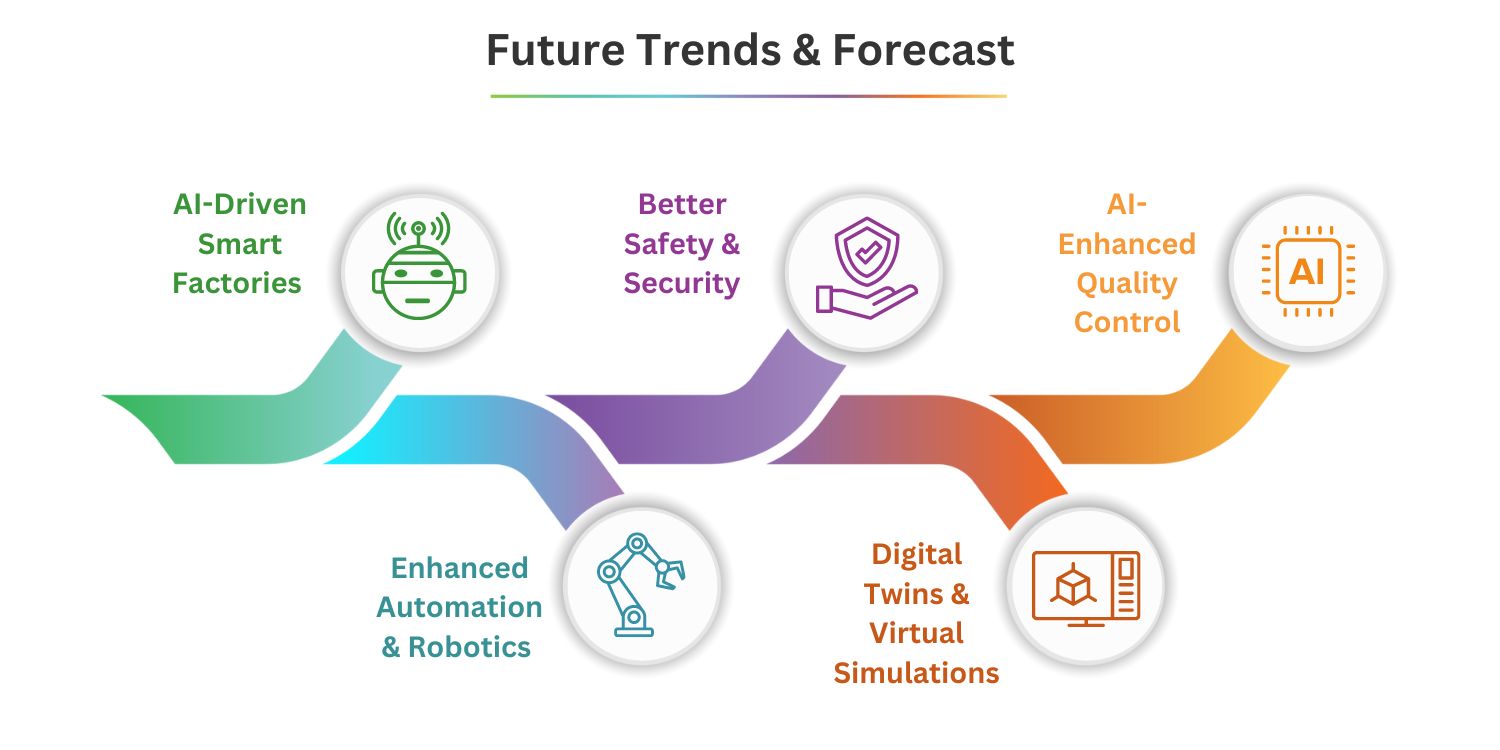

Digital Twins for Virtual Testing and Process Optimization

Digital twins, virtual replicas of manufacturing environments, allow companies to:

- Test new designs and processes without disrupting actual production.

- Identify bottlenecks and inefficiencies.

- Optimize workflows based on simulation results.

Digital twins provide unparalleled insights for manufacturers.

Stay tuned for the second half of this article, where we’ll explore supply chain optimization, the impact of mass customization, and how these innovations will shape the future of manufacturing.